NANO-PROX: Nano-Scale Protective Oxide Films for Semiconductor Applications & Beyond

Introduction to nano-scale protective thin films and their applications in semiconductor manufacturing, interdisciplinary and multidisciplinary aspect and technological quality.

CMP technique is used to induce nano-smoothness and controlled nano/micro scale roughness on the titanium surfaces. Ti based bio implants with self-protective surface oxide layers and controlled roughness formed through CMP to minimize chemical and bacterial reactivity.

Limescale is the hard, off-white, chalky deposit found in kettles, hot-water boilers and the inside of inadequately maintained hot-water central heating systems. It is also often found as a similar deposit on the inner surface of old pipes and other surfaces where “hard water” has evaporated. Other than being unsightly and harder to clean, limescale seriously impairs the operation or damages various components.

Scale inhibitors (anti-scalants) slow the precipitation process of sparingly soluble salts by being absorbed on the forming salt crystals to prevent the attraction of the supersaturated salt to the crystal surfaces. In this situation the crystals never grow to a size or concentration sufficient to fall out of suspension. Furthermore, many scale inhibitors have some dispersive qualities which involve surrounding particles of suspended salt or organic solids with the anionically charged scale inhibitor. Now the anionically charged particles will repel each other to prevent the agglomeration of the particles to larger particles that may precipitate.

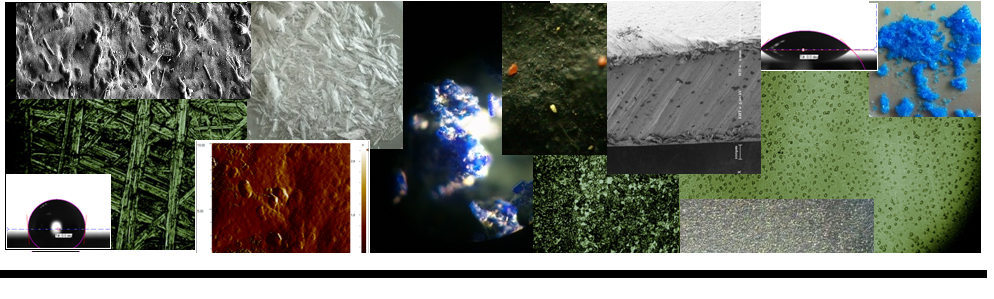

Our work is to use nanomaterials, especially nanocoatings on resistors of washing machines and dishing machines to prevent them from limescale and analyse these coatings by AFM, contact angle, SEM and other devices to find the ideal coating for these resistors.